Capabilities

Johnson Manufacturing Systems is a vertically integrated manufacturer specializing in complex machined parts and assemblies.

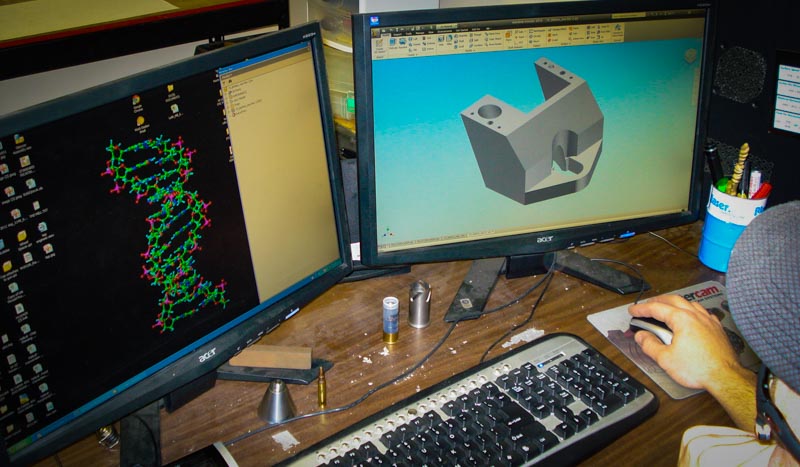

CNC Milling

JMS offers CNC Milling services for product to a maximum work envelope of 60" X x 30" Y x 28" Z. We feature up to 5-axis milling for those difficult jobs, and we ensure accuracy and repeatability with the use of advanced on-board probing techniques to both locate and measure parts when needed. We use only quick-change fixturing for repeat production parts to ensure the most efficient and reliable changeover possible, keeping setup costs to a minimum, and maximizing the value to you the customer.

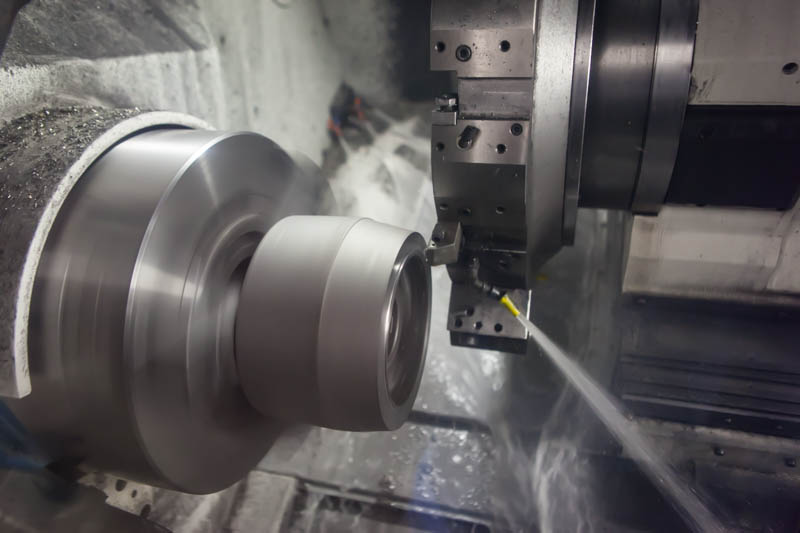

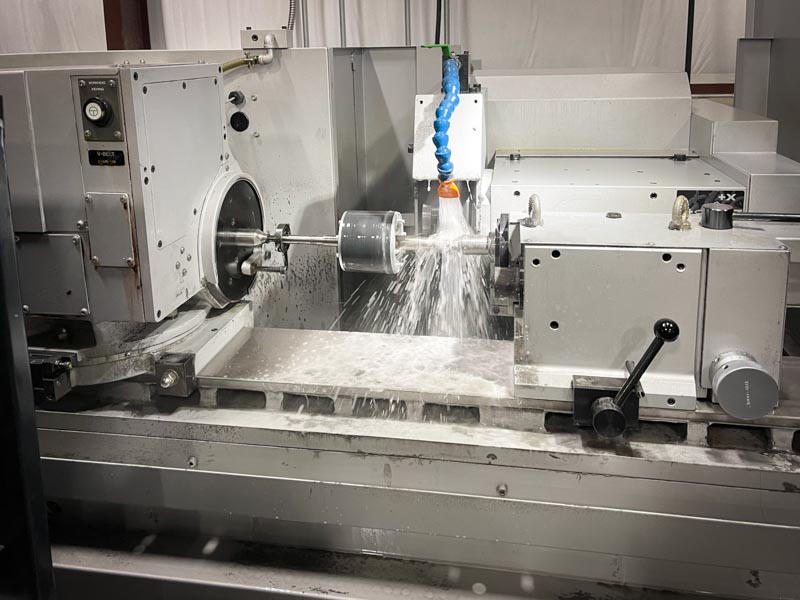

CNC Turning

JMS features Mazak turning centers, with machines ranging from less than 1” dia to over 19” dia x 60” long turning capability with up to 4-axis capabilities. We believe that “right-sizing” the machine to the job ensures the customer gets the machine most optimized in size (and therefore the best price) for each job. Whether you need a one-piece run of a large shaft, or small-medium production runs, we can accommodate your needs.

Design

JMS understands that especially with legacy parts, there may be no 3-D model, or even a formal print! No problem. We have helped many customers whose “blueprint” is a sketch on a notepad formalize, quantify, and tolerance product and tooling. Or we can provide ground-up design for R&D parts, tooling, or new product. Our designers and engineers will work with you through the design process to make sure you get the design right the first time.

Assembly

JMS has also recently added assembly of your customer-supplied components as a standalone service. This was a natural outgrowth from our work internally assembling the components we machine. Ask us how we can help you assemble your products in one of our custom-designed assembly work cells. We will develop the process, tooling, and fixturing, and build your assemblies to your exacting specifications quickly, efficiently, and cost-effectively.

Quality

JMS is committed to providing the highest quality parts possible for the lowest prices. Therefore, we tailor our quality procedures to the needs of each customer and product. We are near compliant to ISO quality standards, and adhere to rigorous internal procedures to ensure quality product is shipped. We are very familiar with and can accommodate your FAI inspection needs using AS9102 forms, and can perform full PPAP if required, including calculation of CpK and gage R&R’s.

Welding

JMS can also provide welded assemblies. With both MIG and TIG expertise welding both ferrous and non-ferrous materials, we will provide you with an assembly that is both structurally sound and aesthetically pleasing.

Process Consulting

A unique service we offer our customers is Manufacturing Process Consulting. With over 30 years’ experience developing numerous manufacturing processes and a Mechanical Engineering degree, our owner Tom Johnson can help you diagnose and treat problems in your manufacturing process, whether it’s scrap, a desire to lean the process, or increasing output. We can also assist with the ground-up design of efficient manufacturing cells.

CNC OD Grinding

Because we specialize in rotating components and assemblies, we have recently added CNC OD grinding to our processing arsenal. Our Okamoto grinders can handle workpieces up to 12" diameter and 30" in length, holding tolerances sometimes less than 0.00005" and surface finishes in the same digits.

Balancing

We also have recently added single-plane or dynamic balancing to our lineup of skills. Ask us about our

balancing capabilities and whether your component or assembly could benefit from being balanced.

"You've got challenges. We have the solutions."